Cumbrian Engineering Service's

Tips for Designing Parts for Machining

Real people with real experience, ready to take on projects of any size.

Trustindex verifies that the original source of the review is Google. Excellent service, always use for routine plant maintenance and reactive works and well as custom fabrication for projects. Adam provides high quality, reliable service at a fair price, essential when maintaining our growing fleet.Trustindex verifies that the original source of the review is Google. Cumbria Access & Engineering worked with me to produce a bespoke height restriction barrier at very short notice for a community garden project. Consulted every step of the way. Amazing attention to detail and quality fitting. have recommended and will be using them again.Trustindex verifies that the original source of the review is Google. Had some work done by Cumbria Access and Engineering, and can't recommend them enough, the work was top quality, exactly to spec, the customer service was great, the lad certainly knows what he's doing, I will be using him again for any other work I need.

Key Takeaways

- Keep geometries simple and easy to machine.

- Use fillets instead of sharp corners for smooth tool access.

- Standardise threads, bores, and tolerances where possible.

- Select materials that balance strength with machinability.

- Design with tool access, setup, and clamping in mind.

- Avoid thin walls or tall features that risk vibration.

- Consider alternative processes like welding or fabrication when machining isn’t ideal.

- Support inspection and measurement with clear design features.

1. Why Machining Design Matters in Cumbria

Designing parts for machining is not just about technical drawings. In areas like Cumbria, where industries rely heavily on plant machinery repairs and custom fabrication, the design stage directly affects cost, turnaround, and quality. Poorly designed parts can lead to wasted material, longer machining times, and repairs that don’t last. From my own experience in North-West UK workshops, a small design oversight—like specifying an unnecessary tight tolerance—can add hours of work and significant costs.

2. Simplify Geometry for Easier Machining

When it comes to machining, simpler is always better. Complex undercuts and unusual curves often require multi-axis CNC machines or custom tooling, which increases costs. Flat surfaces and smooth arcs are far easier to program and machine. The difference in price between that and a standard arc was over 40%. Keeping it simple ensures your design works both technically and economically.

3. Optimising Internal Features with Fillets

Sharp corners are a machinist’s worst enemy. Tools naturally cut in curves, not straight angles. Adding a 3 mm fillet or larger allows standard cutters to move efficiently without leaving stress points. For example, in mechanical engineering projects, we often recommend designing cavities with depths no more than 3–4 times their width. This reduces tool deflection and keeps the part stable during production.

4. Choosing the Right Materials

Material choice can make or break a machining job. Metals like aluminium are easier to cut for complex shapes, while stainless steel demands slower feeds and more expensive tooling. Plastics require different feeds and speeds altogether. For clients in Cumbria, I always suggest starting with what the part needs to withstand wear, pressure, or heat and then narrowing down to a machinable material. This saves both time and rework later on.

5. Standardisation Saves Time and Money

Whenever possible, use standard parts such as common thread sizes and bore diameters. Non-standard threads require specialised taps and cutters that many local shops may not stock. At Cumbria Access & Engineering, we encourage clients to standardise because it not only reduces costs but also ensures replacement parts can be sourced quickly in the future.

6. Applying Tolerances with Care

It’s tempting to specify tight tolerances everywhere, but this approach often leads to unnecessary expense. For instance, a ±0.01 mm tolerance is only needed for high-precision fits, not for a bolt hole that only needs clearance Only apply tight tolerances where they matter such as press-fit shafts or bearing seats.

7. Designing for Tool Access

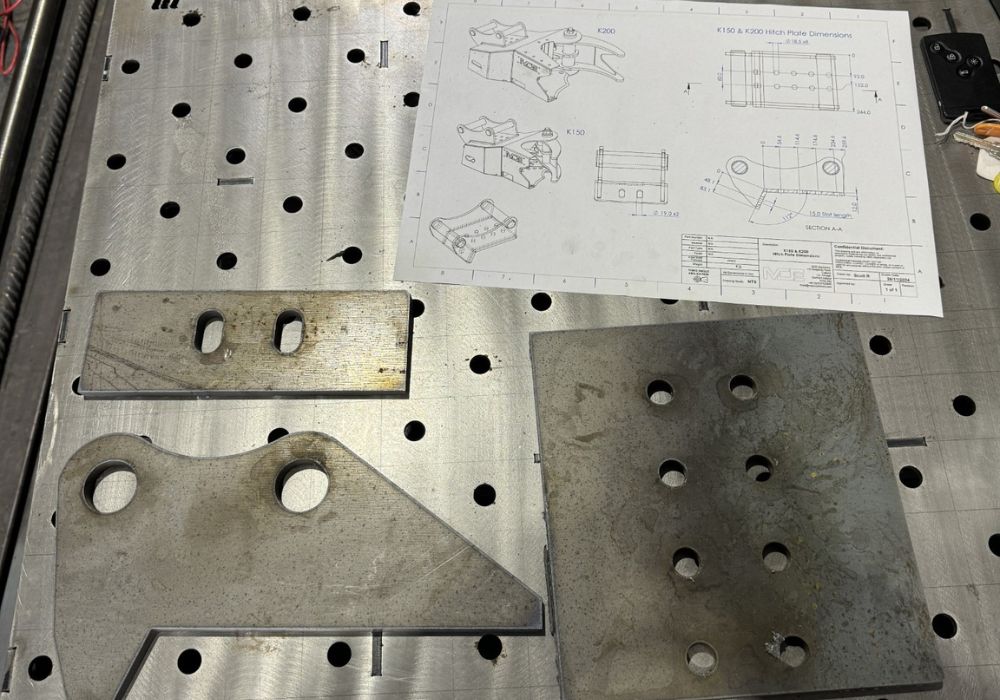

If a tool can’t reach a feature, it can’t be machined. Always design parts so cutters have enough clearance and operators don’t need custom tools. Where possible, consolidate important features onto two or three faces of a part. Too many setups not only waste time but also introduce risk of misalignment. In CNC shops, setup is often half the job, so designing with access in mind saves both cost and quality concerns. For more complex designs, CNC plasma cutting may sometimes offer a quicker alternative.

8. Wall Thickness and Proportions

Thin walls are a recipe for vibration and distortion. For metals, I recommend a minimum of 0.8 mm wall thickness to maintain stiffness. Similarly, tall slender features should be avoided unless absolutely necessary. If a feature’s height exceeds four times its width, vibration becomes a serious risk, leading to poor finishes and potential scrap. When repairing large parts in machining jobs, we often see cracks forming in areas where designers pushed these limits.

9. Supporting Clamping and Measurement

A part is only as good as its inspection. When designing, think about how the component will be held in the machine and how it will later be measured. Providing flat surfaces or reference datums can make a huge difference. For instance, during height restriction gate fabrication, we ensure each gate design has clear points for clamping so that welding or machining processes don’t distort the structure.

10. Alternative Processes Worth Considering

Not every feature is best made through machining. Large cut-outs, for example, may be more efficient with CNC plasma cutting or fabrication. Non-critical areas could be produced with additive manufacturing or simple welding. In Cumbria, where small workshops often handle mixed processes, choosing the right method can save both money and lead time. It’s about designing intelligently for the equipment available locally.

11. Machining in Cumbria: Local Insights

Machining in the North-West UK has its quirks. Many small engineering firms focus on quick turnaround for agricultural and industrial repairs. That means parts need to be designed for fast production, not complex experiments. If you’re working with mewp hire and aerial works or heavy plant machinery, you’ll know downtime is costly. Local machinists value designs that keep setups simple and use readily available materials.

12. Expert Advice for Business Owners in Cumbria

For Cumbria businesses relying on machinery, it pays to develop a good working relationship with local machinists. Provide them with clear drawings, avoid over-specifying, and always ask for their feedback. I often advise business owners to keep a small set of spare standardised parts on hand, reducing downtime in case of breakdown. When in doubt, consult a mechanical engineering expert who can check your designs before machining begins.

Frequently Asked Questions about CNC Plasma Cutting

Keep designs simple with features that standard tools can easily reach.

Use standardised features, avoid unnecessary tolerances, and choose machinable materials.